The company, having calculated its overhead costs as $20 per labor hour, now has a baseline cost-per-hour figure that it can use to appropriately charge its customers for labor and earn a profit. That is, the company is now aware that a 5-hour job, for instance, will have an estimated overhead cost of $100. Most companies will adopt the use of predetermined overhead rates in order to know how their products are performing even before the accounting period ends. It is a way to constantly evaluate the profitability of manufacturing instead of waiting until that reporting period comes to an end. Of course, management also has to price the product to cover the direct costs involved in the production, including direct labor, electricity, and raw materials. A company that excels at monitoring and improving its overhead rate can improve its bottom line or profitability.

Selecting an Estimated Activity Base

Determining this rate involves identifying various entities, including direct labor hours, overhead costs, unit production, and allocation method. The predetermined overhead rate serves as a crucial factor in estimating product costs and assessing cost efficiency, making it essential for businesses to have a well-established understanding of its calculation. The predetermined overhead rate allocates estimated total overhead for an accounting period across expected activity or production volume.

Accounting Ratios

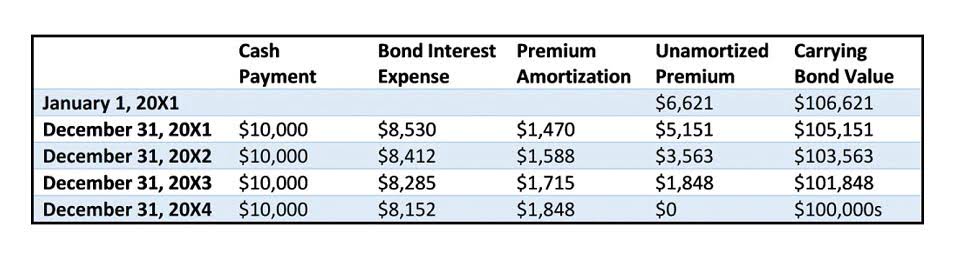

The predetermined overhead rate is, therefore, usually used for contract bidding, product pricing, and allocation of resources within a company, based on each department’s utilization of resources. At the end of the accounting period, you’ll have a difference (called a variance) between your applied overhead (using the predetermined rate) and your actual overhead costs. If you applied more overhead than you actually incurred, that’s an over-applied overhead.

Advantages of predetermined overhead rate formula

The most prominent concern of this rate is that it is not realistic being that it is based on estimates. Since the numerator and denominator of the POHR formula are comprised of estimates, there is a possibility that the result balance sheet will not be close to the actual overhead rate. The fact is production has not taken place and is completely based on previous accounting records or forecasts.

- Examples can include labor hours incurred, labor costs paid, amounts of materials used in production, units produced, or any other activity that has a cause-and-effect relationship with incurred costs.

- The POR is used to apply overhead costs to products or job orders, helping businesses to accurately price their products, manage budgets, and analyze cost behavior.

- The calculation of the plantwide overhead rate first requires gathering the following information.

- The manufacturing overhead costs are applied to the product based on the actual number of activity base units used during the accounting period.

- As the production head wants to calculate the predetermined overhead rate, all the direct costs will be ignored, whether direct cost (labor or material).

- As a collective of industry professionals and enthusiasts, we aim to empower organizations with actionable strategies, innovative tools, and thought leadership that drive value and efficiency.

- The cost of goods sold consists of direct materials of $3.50 per unit, direct labor of $10 per unit, and manufacturing overhead of $5.00 per unit.

Two companies, ABC company, and XYZ company are competing to get a massive order that will make them much recognized in the market. This project is going to be lucrative for both companies but after going over the terms and conditions of the bidding, it is stated that the bid would be based on the overhead rate. This means that since the project would involve more overheads, the company with the lower overhead rate shall be awarded the auction winner. The rate is configured by dividing the assumed overhead amount for a particular period by a certain activity base. Optimize processes – Streamline workflows around everything from inventory to invoicing to save time and cut labor costs. Setting overhead budgets and benchmarks for each department also helps control spending.

Operating Expenses Vs Overhead Expenses

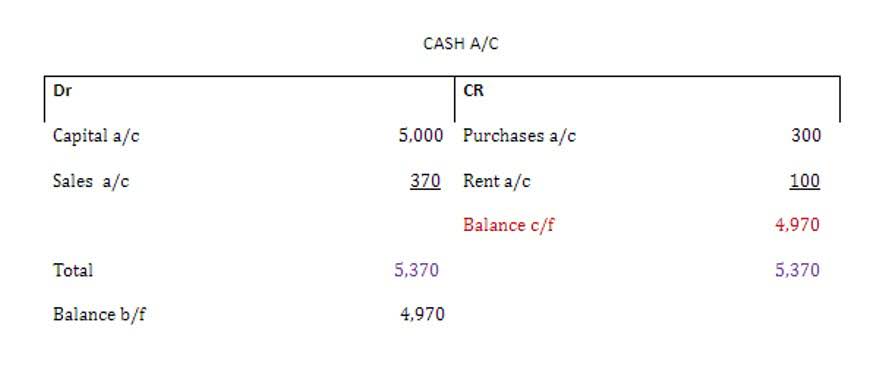

As you have learned, the overhead needs to be allocated to the manufactured product in a systematic and rational manner. This allocation process depends on the use of a cost QuickBooks ProAdvisor driver, which drives the production activity’s cost. Examples can include labor hours incurred, labor costs paid, amounts of materials used in production, units produced, or any other activity that has a cause-and-effect relationship with incurred costs. Next, we look at how we correct our records when the actual and our applied (or estimated) overhead do not match (which they almost never match!). The predetermined overhead rate formula is calculated by dividing the total estimated overhead costs for the period by the estimated activity base. Figure 8.41 shows the monthly manufacturing actual overhead recorded by Dinosaur Vinyl.

Products

In larger companies, each department in which different production processes take place usually computes its own predetermined overhead rate. The formula for a predetermined overhead rate is expressed as a ratio of the estimated amount of manufacturing overhead to be incurred in a period to the estimated activity base for the period. As the production head wants to calculate the predetermined overhead rate, all the direct costs will be ignored, whether direct cost (labor or material).

- As you have learned, the overhead needs to be allocated to the manufactured product in a systematic and rational manner.

- Sales of each product have been strong, and the total gross profit for each product is shown in Figure 6.7.

- GoCardless is a global payments solution that helps you automate payment collection, cutting down on the amount of financial admin your team needs to deal with.

- Manufacturing overhead is allocated to products for various reasons including compliance with U.S. accounting principles and income tax regulations.

- A number of possible allocation bases are available for the denominator, such as direct labor hours, direct labor dollars, and machine hours.

- Overhead rates refer to the allocation of indirect costs to the production of goods or services.

Examples of Overhead Rates

These overhead costs involve the manufacturing of a product such as facility utilities, facility maintenance, equipment, supplies, and labor costs. Whereas, the activity base used for the predetermined overhead rate calculation is usually machine hours, direct labor hours, or direct labor costs. A predetermined overhead rate (OH) is a critical calculation used by businesses to allocate manufacturing overhead costs to products or services. This rate helps in budgeting, pricing, and financial planning by estimating overhead costs in advance rather than waiting for actual figures. Understanding how to calculate this rate ensures accurate cost estimation, leading to better decision-making and profitability.

Another way to view it is overhead costs are those production costs that are not categorized as direct materials or direct labor. When companies begin the planning process of manufacturing a product, cost projections are a large and important focus. Calculating a predetermined overhead rate is one of the first tasks management will take on because it provides a formula to estimate the production costs of a product in advance. Specifically, the predetermined overhead rate is an approximated ratio of manufacturing overhead costs determined in advance based on variable and fixed costs.

Get $20 Off Our PRO Materials

As your business grows and changes, you may need to adjust your rate accordingly. Both plantwide rate and departmental rate are means of estimating the overhead cost allocation to products and services. However, there are a few points of what is predetermined overhead rate differences that make each preferable by firms as per their requirements and suitability. Hence, this predetermined overhead rate of 66.47 shall be applied to the pricing of the new product VXM. Understanding these formulas allows businesses to budget for overhead, set predetermined rates, analyze variances, and adjust rates accordingly.